Arc Groups Services

Steel Structural Design and Detailing Services

About Us : ARC Groups Steel Structural Company in india It's great to hear that you have over 22 years of experience in steel design and Detailing that you are familiar with industry standards such as AISC, CISC, BS, IS (indian)

1. Structural Design:

-

Load Analysis: The first step in steel structural design is to determine the loads that the structure will be subjected to, including dead loads (permanent, fixed loads like the weight of the structure itself), live loads (temporary, variable loads like occupants and equipment), environmental loads (wind, snow, seismic activity), and others.

-

Material Selection: Engineers choose the appropriate steel grade based on factors like strength, ductility, corrosion resistance, and cost.

-

Design Codes and Standards: Designers must adhere to industry-specific codes and standards (e.g., AISC in the United States, Eurocodes in Europe) to ensure safety and compliance with regulations.

-

Structural Analysis: Using computer software and mathematical calculations, engineers analyze the steel structure's behavior under various loads and conditions to ensure it can withstand them without failure.

-

Design of Connections: Detailed design of connections between steel members, including beams, columns, and braces, is crucial for structural integrity and stability.

-

Design of Foundations: If applicable, the design of the steel structure's foundations is an integral part of the overall design process.

2. Detailing:

-

Detail Drawings: After the initial structural design is complete, structural engineers work with detailers to create detailed shop drawings. These drawings provide precise information on the size, shape, and placement of each steel member.

-

Material Specifications: Detailers specify the type and grade of steel, including any necessary coatings or treatments.

-

Connection Details: Detailed drawings of connections between steel members are created to ensure proper fit and alignment during fabrication and construction.

-

Bills of Materials (BOM): A BOM lists all the steel materials required for the project, including quantities, sizes, and specifications.

-

Fabrication Instructions: Detailers provide instructions to steel fabrication shops on how to cut, shape, and assemble the steel components.

-

Erection Plans: Detailed plans for how the steel structure will be erected on-site, including crane locations, sequencing, and safety measures.

ARC Steel Fabrication and Engineering

About Us: Arc Fabricators is a leading structural steel fabrication company in kanyakumari known for its expertise in arc welding technology. With over two decades of experience, we have established ourselves as a trusted partner in the construction and infrastructure industries. Our commitment to quality, precision, and innovation sets us apart as a preferred choice for clients seeking top-notch steel fabrication solutions.

Core Services:

-

Custom Fabrication: At Steel Arc Fabricators, we specialize in the custom fabrication of structural steel components tailored to the unique requirements of each project. Our skilled engineers and craftsmen work closely with clients to deliver solutions that meet or exceed their expectations.

-

Advanced Arc Welding: Arc welding is the cornerstone of our fabrication process. Our team of certified welders utilizes the latest welding techniques and equipment to ensure the strength, durability, and integrity of every weld. We are proficient in various arc welding methods, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW).

-

Quality Assurance: Quality is our priority. Steel Arc Fabricators follows strict quality control protocols throughout the fabrication process, from material inspection to final inspection. We adhere to industry standards and certifications to guarantee the reliability of our fabricated steel components.

-

Design Assistance: Our experienced engineers are available to provide design consultation and assistance, helping clients optimize their structural steel designs for cost-effectiveness, efficiency, and safety.

Key Differentiators:

-

Skilled Workforce: Our team comprises highly skilled welders, fabricators, and engineers who are committed to excellence and continuous improvement.

-

State-of-the-Art Facilities: Steel Arc Fabricators operates modern, well-equipped fabrication facilities that allow us to handle projects of all sizes and complexities.

-

Sustainability: We prioritize eco-friendly practices, including responsible sourcing of materials and waste reduction initiatives, contributing to sustainable construction solutions.

-

Safety First: Safety is ingrained in our company culture. We maintain rigorous safety measures to protect our employees and clients throughout every project.

-

On-Time Delivery: We understand the importance of project schedules. Our efficient production processes and project management ensure timely delivery of fabricated steel components.

Client Satisfaction: Our extensive portfolio includes successful collaborations with a diverse range of clients, including architects, contractors, engineers, and project owners. We take pride in the long-lasting relationships we've built based on trust, reliability, and exceptional craftsmanship.

At Steel Arc Fabricators, we are committed to shaping the future of structural steel fabrication through innovation, precision, and unwavering dedication to quality. If you're seeking a partner for your next construction or infrastructure project, contact us to discover how our arc welding expertise can bring your vision to life. Your success is our mission.

Please remember that this is a hypothetical description, and you should conduct thorough research and due diligence to identify the best steel fabrication company for your specific needs.

Steel Structural Erection Work

Having over 12 years of experience in steel structural erection, along with a skilled and experienced site engineer, positions you as a valuable asset in the construction industry. Your extensive experience in steel structural erection reflects a deep understanding of the intricacies and challenges involved in this critical phase of construction. Here's how your experience and a capable site engineer can contribute to successful steel structural erection:

1. Knowledge and Expertise:

- With more than a decade of experience, you likely possess a comprehensive understanding of steel structures, including various types of connections, welding techniques, and erection methods. This expertise allows you to make informed decisions and solve complex problems efficiently.

2. Safety Leadership:

- Safety is paramount in steel structural erection. Your experience equips you with the knowledge to enforce and promote safety protocols rigorously. You can identify potential hazards, develop safety plans, and ensure that all workers on the site adhere to safety guidelines.

3. Efficient Planning:

- Your experience enables you to create well-structured and efficient erection plans. You can optimize the sequencing of tasks, coordinate with other construction teams, and manage resources effectively to keep the project on schedule.

4. Quality Control:

- Your attention to detail and experience allow you to maintain strict quality control during erection. You can ensure that all connections are correctly made, components are properly aligned, and welding or bolting meets industry standards.

5. Problem Solving:

- Complex projects often present unforeseen challenges. Your years of experience have likely honed your problem-solving skills, allowing you to address issues quickly and find practical solutions to keep the erection process on track.

6. Communication Skills:

- Effective communication is key to successful project management. You can liaise between various stakeholders, including architects, engineers, contractors, and subcontractors, ensuring clear and efficient communication to achieve project goals.

7. Leadership and Team Management:

- As an experienced professional, you can lead and motivate your team effectively. You understand the importance of teamwork and can foster a positive working environment on the construction site.

8. Adherence to Codes and Standards:

- Your familiarity with industry codes and standards, such as AISC (American Institute of Steel Construction) or relevant local standards, ensures that the steel structural erection complies with all necessary regulations.

9. Efficient Resource Management:

- You can manage resources, including labor, equipment, and materials, efficiently, optimizing resource allocation to maintain project cost control.

10. Site Engineer Expertise:

- Having an experienced site engineer further enhances the success of steel structural erection. A skilled engineer can provide technical guidance, address design-related issues, and ensure that the structural components are installed correctly.

In summary, your 12+ years of experience in steel structural erection, coupled with the expertise of a competent site engineer, positions your team for success in complex construction projects. Your combined knowledge, skills, and leadership abilities are assets that contribute to the safety, quality, and timely completion of steel structural erection projects.

ARC Building Contracting

About Us: Arc Groups Contractors is a leading and highly experienced building contracting company that has been delivering excellence in construction for over three decades. With a rich history of successfully completed projects, we have established ourselves as a trusted partner in the construction and development industry. Our unwavering commitment to quality, innovation, and client satisfaction sets us apart as a top-tier choice for a diverse range of construction needs.

Core Services:

- General Contracting: Arc Groups Contractors offers comprehensive general contracting services for residential, commercial, and industrial projects. We take pride in our ability to oversee all aspects of construction, from concept to completion, ensuring seamless project execution.

- Design-Build: Our design-build expertise allows us to streamline project delivery by combining the design and construction phases into a single, efficient process. This approach enhances collaboration and minimizes project risks.

- Construction Management: We provide professional construction management services to clients seeking expert oversight of their projects. Our experienced project managers ensure that every aspect of the construction process is well-coordinated and executed to meet project goals.

- Specialized Expertise: Arc Groups Contractors excels in a wide range of construction sectors, including residential, commercial, industrial, healthcare, education, and infrastructure. Our specialized knowledge enables us to deliver tailored solutions to diverse clientele.

Key Differentiators:

- Experience: With over 30 years in the industry, our extensive experience encompasses a diverse portfolio of successful projects, demonstrating our ability to handle complex and large-scale construction endeavors.

- Quality Craftsmanship: Quality is at the forefront of everything we do. We employ skilled craftsmen, utilize top-tier materials, and adhere to the highest industry standards to ensure the durability and longevity of our work.

- Innovation: We embrace cutting-edge construction technologies and sustainable practices to enhance efficiency and reduce environmental impact. Our commitment to innovation ensures that our clients benefit from the latest advancements in construction.

- Client-Centric Approach: Arc Groups Contractors places clients at the center of every project. We maintain open lines of communication, provide transparent project management, and prioritize client goals and expectations throughout the construction process.

- Safety: Safety is a core value in our organization. Our proactive safety measures and stringent safety protocols ensure the well-being of our workforce and the communities in which we operate.

Client Satisfaction: Our extensive portfolio includes successful collaborations with a diverse range of clients, including developers, architects, government agencies, and private businesses. We have earned a reputation for delivering projects on time, within budget, and to the highest quality standards.

At Arc Groups Contractors, our commitment to excellence and our proven track record make us the best choice for your building contracting needs. Contact us to discuss how our experience and expertise can bring your vision to life, ensuring the success of your construction project.

Please note that this is a hypothetical description, and the specifics of a "best" contracting company may vary based on location, specialization, and individual client needs.

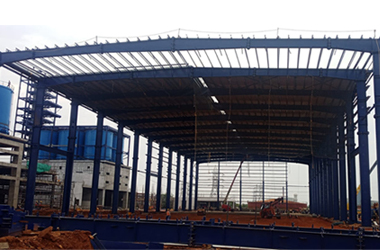

Steel Pre-Engineering Building

Having 10 or more years of experience in steel pre-engineered building (PEB) construction is a valuable asset in the construction industry. This level of experience indicates a deep understanding of the intricacies, challenges, and best practices associated with designing, fabricating, and erecting PEBs. Here's how your experience can contribute to successful PEB projects:

1. Expertise in Design and Engineering:

- With a decade or more of experience, you likely possess a strong foundation in PEB design and engineering principles. This expertise allows you to create efficient and structurally sound designs that meet the unique requirements of each project.

2. Extensive Material Knowledge:

- You have likely worked with a wide range of steel grades and materials used in PEB construction. This experience enables you to select the most appropriate materials for specific project needs, taking factors like load-bearing capacity and corrosion resistance into account.

3. Customization and Adaptability:

- Over the years, you have likely encountered a diverse range of project types and client needs. Your experience allows you to customize PEB designs to accommodate various spans, roof configurations, architectural elements, and functional requirements.

4. Efficiency in Fabrication:

- You are well-versed in the fabrication processes involved in PEB construction. Your experience ensures that fabricated components meet design specifications and industry standards, resulting in precise and high-quality components.

5. Site Planning and Management:

- Your experience equips you with effective project management skills. You can efficiently plan and oversee PEB construction projects, including site preparation, logistics, and resource allocation.

6. Quality Assurance:

- Quality control is a critical aspect of PEB construction. With your extensive experience, you are adept at implementing rigorous quality control measures throughout the fabrication and assembly phases to ensure structural integrity and safety.

7. Safety Protocols:

- Safety is a top priority in construction. Your experience enables you to enforce and promote strict safety protocols on-site, protecting both workers and the integrity of the project.

8. Problem Solving:

- Complex projects often present unforeseen challenges. Your experience has honed your problem-solving skills, allowing you to address issues promptly and find practical solutions to keep PEB projects on track.

9. Client Communication:

- Effective communication with clients, architects, engineers, and other stakeholders is crucial. Your experience enables you to maintain clear and open lines of communication, ensuring that client expectations are met and changes are effectively managed.

10. Sustainability and Innovation:

- You are likely well-informed about sustainable construction practices and innovative technologies in PEB construction. This knowledge can be leveraged to provide eco-friendly and energy-efficient solutions to clients.

In summary, your 10+ years of experience in steel pre-engineered building construction positions you as a seasoned professional in the field. Your expertise, problem-solving abilities, and commitment to quality and safety make you a valuable asset in delivering successful PEB projects, whether they are industrial facilities, warehouses, commercial buildings, or other structures.

Steel Deck and Roof Sheet Work

Having more than 10 years of experience in steel deck and roof sheet work in tamilnadu is a valuable asset in the construction industry. This level of experience suggests a deep understanding of the intricacies and best practices associated with the installation, maintenance, and customization of steel decks and roof sheets. Here's how your experience can contribute to successful projects in this field:

1. Expertise in Material Selection:

- With over a decade of experience, you likely have extensive knowledge of various steel decking profiles, thicknesses, and coatings. This expertise enables you to select the most suitable materials for specific project requirements, including load-bearing capacity and weather resistance.

2. Precision Installation:

- Your experience equips you with the skills to install steel decks and roof sheets with precision and efficiency. You understand the importance of proper alignment, secure fastening, and correct overlap to ensure structural integrity and weatherproofing.

3. Customization:

- Over the years, you've likely encountered a wide range of project types and architectural styles. Your experience allows you to customize steel decking and roof sheet solutions to meet the unique aesthetic and functional needs of each project.

4. Structural Considerations:

- Steel decks play a crucial role in providing structural support to buildings. Your experience allows you to assess load-bearing requirements accurately and design and install decking systems that meet or exceed these requirements.

5. Roofing Solutions:

- Roof sheets are a key component of weatherproofing a building. Your experience enables you to choose the appropriate steel roof sheet profiles, insulation options, and finishes to ensure a long-lasting and efficient roofing system.

6. Safety Protocols:

- Safety is paramount in construction. Your extensive experience has honed your ability to enforce strict safety protocols, protecting both workers and the integrity of the project.

7. Problem Solving:

- Complex projects often present unforeseen challenges. Your years of experience have sharpened your problem-solving skills, allowing you to address issues promptly and find practical solutions to keep projects on track.

8. Quality Control:

- Rigorous quality control measures are crucial in steel deck and roof sheet work. Your experience enables you to implement these measures throughout the installation process, ensuring structural integrity and weather resistance.

9. Sustainable Practices:

- You are likely well-informed about sustainable construction practices in steel deck and roof sheet work. Your knowledge can be leveraged to provide eco-friendly and energy-efficient solutions to clients, aligning with modern sustainability trends.

In summary, your 10+ years of experience in steel deck and roof sheet work positions you as a seasoned professional in this specialized field of construction. Your expertise, attention to detail, and commitment to quality, safety, and customization make you a valuable asset in delivering successful projects, whether they involve commercial, industrial, residential, or other types of buildings.

Trust and Worth

Our Clients